July 26th, 2024

Digital BOP Assurance (DBA)

Time-Based Maintenance vs. Condition-Based Maintenance for Subsea BOPs

The offshore drilling industry has long relied on time-based maintenance (TBM) for Blowout Preventers (BOPs), following OEM schedules. This often results in maintaining components too early or too late, causing unnecessary non-productive time (NPT) and affecting efficiency and costs. To address these issues, the industry is shifting towards Condition-Based Maintenance (CBM).

Unlike TBM, CBM uses real-time data and analytics to predict maintenance needs, minimizing NPT by addressing issues before they cause failures.

Join our Newsletter to stay up to date on new Advancements, Announcements & More

Benefits of Condition Based Maintenance

Condition-Based Maintenance (CBM) offers several significant advantages over traditional time-based maintenance (TBM):

Improved Reliability: Maintenance is performed only when necessary, reducing unexpected failures.

Greater Efficiency: eliminates unnecessary maintenance, preserves BOP parts & spares and prevents wasted spending.

Enhanced Safety: Continuous monitoring and real-time analytics enhance safety.

Data-Driven Decisions: Informed decisions based on actual equipment conditions, not schedules.

How Aquila Provides the Industry with Condition-Based Maintenance

Aquila Engineering’s Digital BOP Assurance (DBA) service is at the forefront of condition-based maintenance. Our advanced data analytics continuously monitor BOP performance and condition to ensure optimal operation. Here’s how we do it:

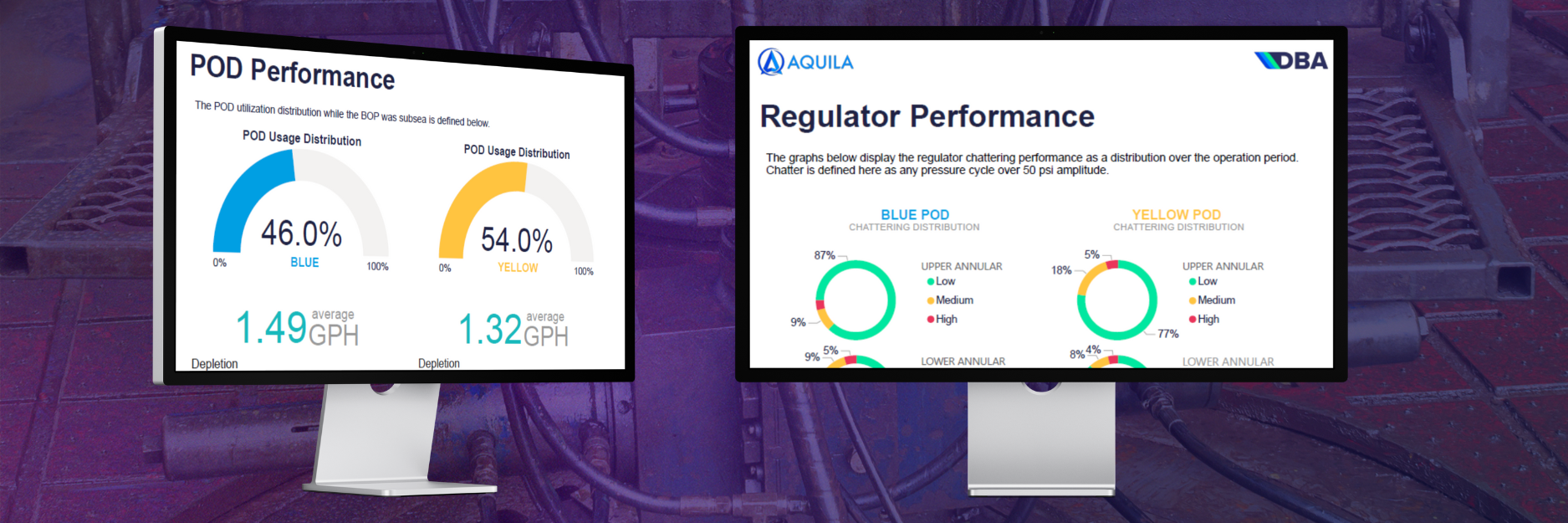

Data Collection: We gather data from BOPs, including well control events, POD utilization, fluid depletion, and regulator performance.

Analysis and Reporting: Our analytic tools generate detailed reports on BOP health and performance.

Recommendations: We provide actionable recommendations, ensuring timely and effective maintenance.

Through these steps, Aquila Engineering delivers reliable, efficient, and data-driven condition-based maintenance solutions to the industry.

Example of a Condition-Based Maintenance Report

An example CBM report includes key observations and recommendations, such as fluid depletion rates and differential pressures. These insights allow operators to address potential issues before they escalate, ensuring compliance with standards like API STD 53.

Advancing CBM with Predictive Analytics

Aquila has taken the CBM concept to the next level by incorporating predictive analytics to reduce NPT and maximize maintenance events. Our annular health model and regulator chatter analysis (seen above) dashboards are prime examples of how we use predictive analytics to anticipate and address potential issues before they cause operational disruptions. These tools help operators make proactive decisions, further enhancing the reliability and efficiency of their BOP systems.

Leading Innovation in BOP Maintenance & Reliability

Aquila Engineering is consistently innovating traditional methods for BOP reliability and leading the industry with cutting-edge solutions. By integrating condition-based maintenance with advanced predictive analytics, we offer our clients unparalleled support and assurance. Our proactive approach ensures enhanced safety, operational efficiency, and reliability. Contact us to learn more about our CBM services and how we can support your offshore drilling operations.