November 15th, 2024

Revolutionize BOP Testing with Aquila DPT: Enhanced Efficiency and Reliability

Aquila DPT and its many advantages during BOP maintenance and equipment testing

Using DPT (Digital Pressure Testing) software has become more widely accepted and preferred across the industry because of its reliability and ease of use. Aquila's DPT package can be used for testing almost everything from component operating chamber tests of rebuilt BOP components and yearly operator testing PMs by the drilling contractors to Pre-deployment BOP stump testing and seafloor testing by the rig operators. Additionally, Aquilas DPT has built-in safety features to help prevent unintentional overpressure of components above their rated working pressure.

In this blog, we'll explore how Aquila's Digital Pressure Testing (DPT) software enhances BOP testing, saves time, and improves safety. From component testing to pre-deployment checks, DPT’s ease of use and customizable features are streamlining operations across the industry.

Why DPT is Revolutionizing BOP Testing with Built-In Safety Features

Aquila DPT software is an increasingly preferred choice for testing due to its user-friendly interface, robust capabilities, and unmatched reliability. From testing individual BOP components after a rebuild to running operator testing as part of routine maintenance, DPT seamlessly covers a wide range of testing needs. Additionally, its application isn’t limited to BOPs alone; Aquila DPT is a versatile tool used in various contexts, including Managed Pressure Drilling (MPD) systems and Control Mud Level (CML) equipment. By allowing operators to replace traditional chart recorders and subjective evaluations, DPT delivers precise digital records and helps ensure thorough and accurate testing.

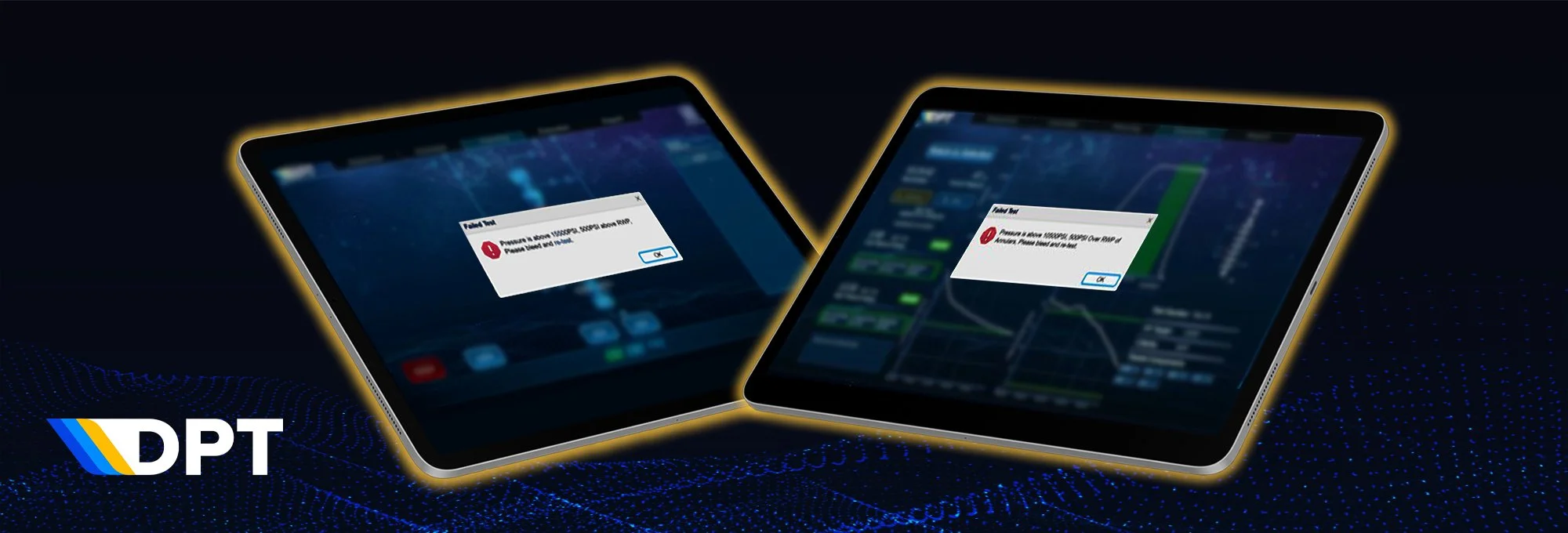

Safety is paramount in equipment testing, and Aquila DPT leads the industry with innovative safety mechanisms. One such feature is the Overpressure Warning Popup, which alerts the operator before pressures exceed the component's rated working limit, helping to prevent potential equipment damage and ensuring compliance with industry standards. These safety features are particularly critical during pressure tests where an overpressure event could lead to costly downtime or repairs.

An Industry-Leading Interface and Proven Time-Saving Tool for BOP Maintenance

Recently, one of our clients in the Gulf of Mexico (GOM) used Aquila DPT to complete operator chamber testing on rebuilt shear ram bonnets and annular equipment. DPT not only provided them with real-time pressure data but also generated baseline test records, such as minimum piston movement pressure and locking/unlocking pressure levels. This level of detail supports informed maintenance, tracking, and verification—enhancing the equipment's overall safety and reliability.

Moreover, each test report from Aquila DPT can be downloaded in PDF format for easy integration into the client’s maintenance records. This ensures that all test data is readily available, accurate, and accessible, facilitating smoother audits and historical performance tracking.

Aquila DPT’s straightforward interface is designed with operators in mind, making it highly intuitive to use. From an easily navigable Test Execution page to the capability to incorporate custom schematics, every aspect of DPT has been optimized to facilitate a streamlined experience for users. Training options, including on-site training with Aquila Field Service Engineers (FSEs) or instructional PowerPoint sessions, are available to ensure operators feel confident and knowledgeable in using the software. And, should questions arise, Aquila's support is just a message away via Microsoft Teams, providing instant assistance when needed.

Ensuring High Pressure Compliance and Custom Testing with Aquila DPT

Pre-deployment stump testing and seafloor latch-up testing are crucial for BOP deployment, ensuring that each component meets its target pressure before going operational. Aquila DPT simplifies this process with a customized component matrix that tailors each test kit to the specific needs of the rig. This matrix-driven approach ensures that all BOP and choke manifold components are tested accurately, with clear guidelines for compliance. For instance, the application will automatically fail tests if API compliance is violated—such as exceeding 5% of the RWP, or reaching high pressures like 15,500 PSI on the left tablet or 10,500 PSI on the right tablet during latch-up tests. It also ensures proper pressurization for low-pressure tests, automatically reinitializing if pressure reaches 500 PSI.

While designed primarily for BOP systems, Aquila DPT’s versatility extends to MPD and CML systems, as well as other surface equipment like production trees, coil tubing, and safety valves. Custom schematics allow for seamless integration, and any equipment with available power and pressure transducers can be tested. By moving away from traditional tools like chart recorders, DPT provides precise digital records, reducing human error and saving valuable time, ensuring a thorough, compliant testing process across the platform.

Aquila DPT is setting new standards in equipment testing by moving beyond outdated technology. With its digital precision, real-time monitoring, and secure data archiving, DPT offers a superior alternative to traditional methods, eliminating subjective evaluations and providing reliable, standardized results. The digital reports ensure clarity, transparency, and cost-efficiency.

As the offshore industry evolves, Aquila DPT is transforming BOP maintenance and testing processes by simplifying complex tasks, enhancing safety, and delivering instant access to critical data. This innovation improves workflow, reduces downtime, and ensures the highest quality in every test, making it the go-to solution for operators and rig managers alike.