February 14th, 2025

The Game-Changer: Digital Pressure Testing in Oil and Gas

Achieving Peak Performance and Safety with Digital Pressure Testing

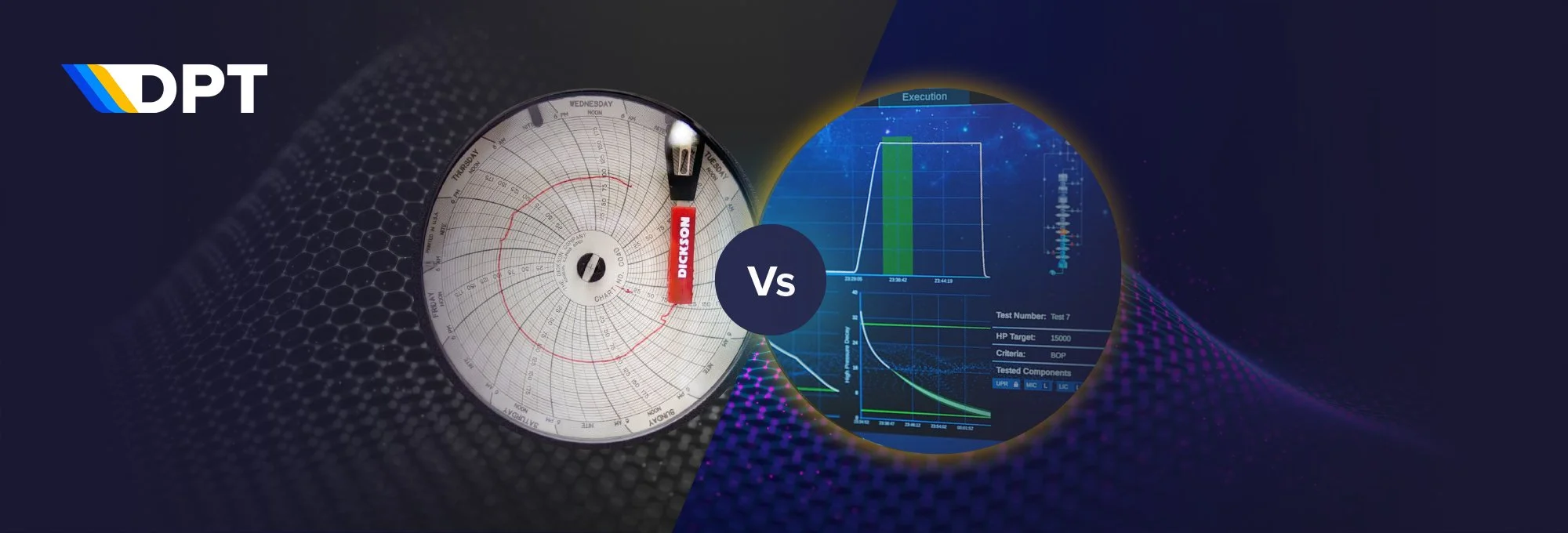

Pressure testing is a fundamental aspect of oil and gas operations, ensuring that critical equipment and systems can withstand the extreme pressures they encounter during production. Traditionally, this process has involved manual methods prone to human error, which can lead to costly delays, safety risks, and operational inefficiencies. Enter digital pressure testing—a transformative approach that leverages technology to improve accuracy, enhance safety, and streamline operations. Here’s how eliminating human error through digital pressure testing is reshaping the industry and how Aquila is leading the charge.

In this blog, we explore how Aquila’s Digital Pressure Testing solutions eliminate human error, enhance safety, and optimize efficiency, empowering operators to make real-time, data-driven decisions and improve overall performance in the oil and gas industry.

Conventional pressure testing methods often require manual data entry, observation, and interpretation, leaving room for human error. Some common issues include:

Inaccurate Readings: Manual recording of pressure readings can lead to transcription errors or missed anomalies.

Subjective Interpretation: Identifying whether a pressure drop is within acceptable limits can be subjective, relying heavily on the operator’s experience.

Delayed Decisions: The time required to collect, analyze, and act on data manually can delay critical operations.

Safety Risks: Errors in pressure testing can compromise equipment integrity, increasing the risk of blowouts or other hazardous incidents.

These challenges highlight the need for a more reliable and efficient approach to pressure testing—one that minimizes human error and ensures consistent, accurate results.

The Problem with Traditional Pressure Testing

Digital pressure testing replaces manual processes with automated systems that collect, analyze, and store data in real time. This technology offers several key benefits:

Enhanced Accuracy Digital systems automatically record pressure readings, eliminating the risk of transcription errors. Real-time data collection ensures that no critical information is missed.

Objective Analysis Advanced algorithms analyze pressure data to detect anomalies, removing the subjectivity associated with manual interpretation. These systems provide clear, actionable insights.

Faster Decision-Making With instant access to accurate data, operators can make informed decisions quickly, reducing downtime and keeping projects on schedule.

Improved Safety Digital systems monitor pressure levels continuously and can trigger alarms or automated shutdowns if unsafe conditions are detected, significantly reducing the risk of accidents.

Data Integrity and Traceability Digital pressure testing systems store data securely, enabling detailed record-keeping and compliance with regulatory requirements. This traceability is essential for audits and incident investigations.

The Digital Pressure Testing Advantage

Aquila’s Role in Digital Pressure Testing

Aquila is at the forefront of digital innovation in the oil and gas industry, offering cutting-edge solutions for digital pressure testing. By integrating advanced analytics and real-time monitoring into Blowout Preventer (BOP) assurance systems, Aquila ensures the highest level of precision and reliability in pressure testing operations.

Here’s how Aquila is making an impact:

Automated Testing Processes Aquila’s systems automate the entire pressure testing process, from data collection to analysis, minimizing human involvement and potential errors.

Real-Time Monitoring With continuous monitoring capabilities, Aquila’s solutions provide operators with immediate feedback on pressure conditions, enabling quick responses to potential issues.

Predictive Analytics Using machine learning and data analytics, Aquila identifies trends and predicts potential equipment failures before they occur, enhancing operational efficiency and safety.

Regulatory Compliance Aquila’s digital solutions ensure that all pressure testing data is recorded and stored in compliance with industry regulations, simplifying audits and reducing administrative burdens.

Transforming Operations with Digital Precision

The shift to digital pressure testing is more than just a technological upgrade—it’s a cultural shift toward prioritizing safety, efficiency, and accountability. By eliminating human error, companies can reduce costs, prevent accidents, and maintain uninterrupted operations.

Aquila’s innovative approach to digital pressure testing exemplifies how technology can drive meaningful change in the oil and gas industry. By combining precision with proactive risk management, Aquila is helping companies achieve higher standards of performance and safety.

The Future of Pressure Testing

As digital transformation continues to reshape the oil and gas sector, the adoption of digital pressure testing will only accelerate. Companies that embrace this technology today will be better positioned to navigate the challenges of tomorrow, from increasing regulatory demands to the growing need for sustainable operations.

With leaders like Aquila paving the way, the future of pressure testing is not just digital—it’s smarter, safer, and more reliable. By eliminating human error, the industry is building a stronger foundation for success in an increasingly complex and competitive landscape.