April 6th, 2024

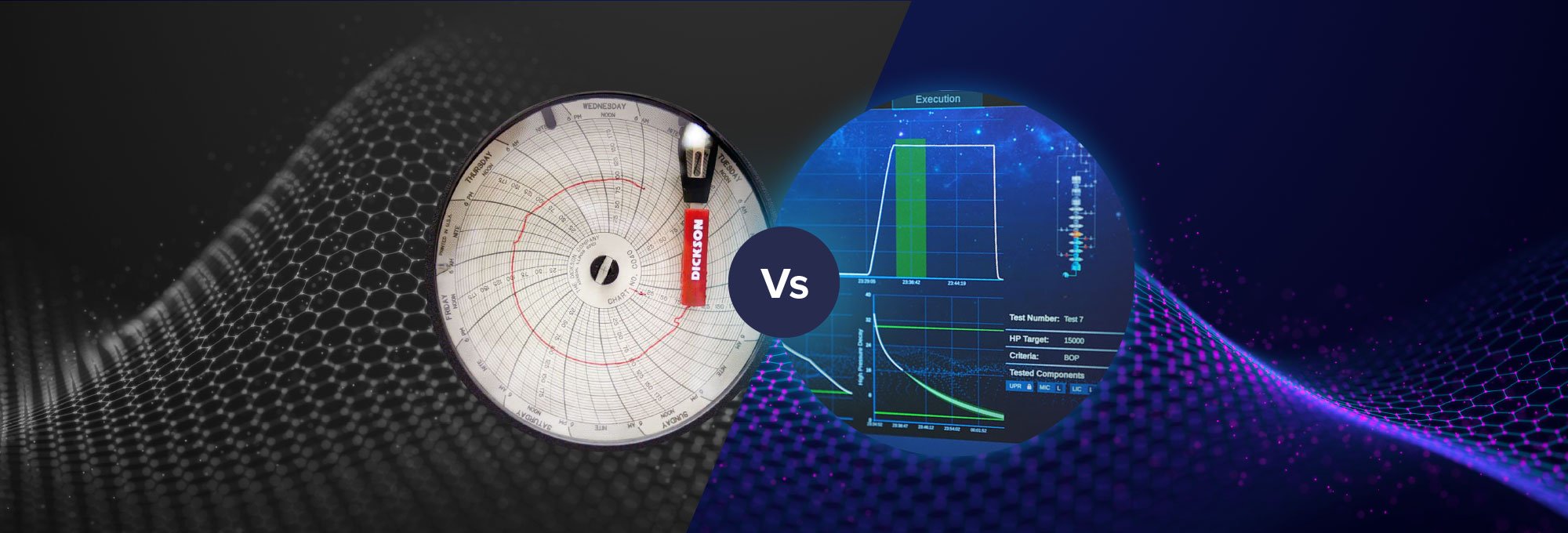

Traditional vs Digital Pressure Testing

Circular charts vs digital pressure testing in well control equipment

In the oil and gas industry, the integrity and reliability of well control equipment, such as Blowout Preventers (BOPs), are paramount for operational safety and efficiency. Over the years, the methods for pressure testing these critical pieces of equipment have evolved from traditional hydraulic circular chart recordings to advanced digital pressure testing.

This blog delves into the comparative analysis of these two methodologies, highlighting their pros and cons, especially focusing on the human factor in interpreting hydraulic charts and the organizational benefits of digital solutions.

Join our Newsletter to stay up to date on new Advancements, Announcements & more

The Era of Mechanical Circular Charts

Circular charts have been the cornerstone of pressure testing for decades, offering a visual representation of pressure changes over time. These charts, driven by a clock mechanism, record data on a circular paper, providing a continuous graph of pressure variations. The primary advantage of this method has been its simplicity and direct mechanical link to the pressure being monitored, requiring no electricity or complex systems to function.

However, this simplicity comes with a significant flaw: the reliance on human interpretation. Reading mechanical circular charts demands a high degree of experience and skill. The operator must discern subtle changes in the graph, a process prone to human error. Misinterpretation can lead to overlooking critical pressure fluctuations, potentially compromising the safety and integrity of well control operations.

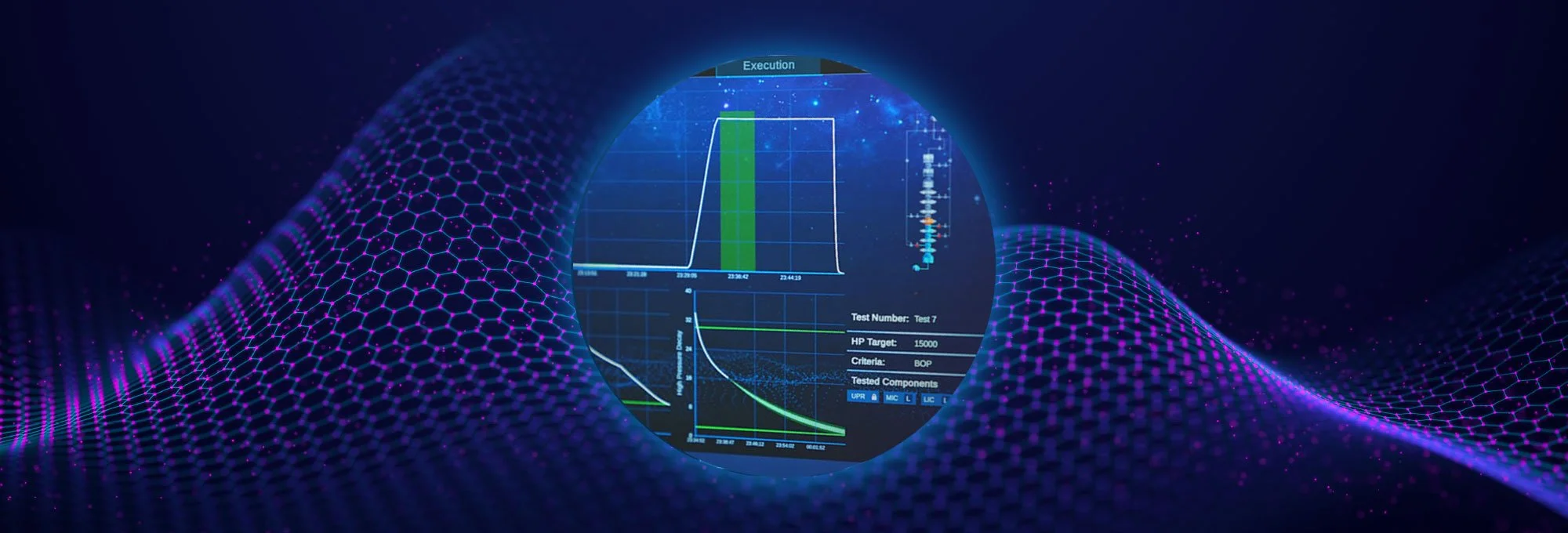

Transition to Digital Pressure Testing

The advent of digital pressure testing technologies has transformed well control equipment testing, offering precision, ease of use, and enhanced safety. Digital pressure sensors provide real-time data acquisition, high accuracy, and the ability to store and process vast amounts of data efficiently. This leap in technology mitigates the risk of human error associated with manual chart interpretation.

One of the most significant advantages of digital pressure testing is its contribution to organizational efficiency and documentation. Digital systems automate data collection and analysis, seamlessly integrating test results into reports. This not only speeds up the decision-making process but also ensures a high level of accuracy and reliability in the documentation. The ability to quickly organize, access, and review historical data facilitates better planning and compliance with regulatory standards, enhancing the overall safety and efficiency of well control operations.

Advantages of Digital Over Circular Charts

Accuracy and Reliability

Digital sensors provide more accurate and consistent readings than manual interpretations of hydraulic charts.

Efficiency

Automated data collection and analysis reduce the time required for testing, evaluating data, and reporting.

Documentation

Digital systems offer superior capabilities for data storage,

retrieval and management, ensuring comprehensive and reliable documentation for compliance and review.

Safety

Minimizing human error in data interpretation enhances the safety and integrity of well control equipment.

Conclusion

While circular charts have historically provided valuable service in the testing of well control equipment, the evolution towards digital pressure testing methodologies marks a pivotal advancement in ensuring operational safety and efficiency. Aquila Digital Pressure Testing, leading the charge in this digital transformation, offers an exemplary solution that addresses the limitations of manual chart interpretation. By leveraging high-precision sensors and advanced data analytics, Aquila ensures unparalleled accuracy, efficiency, and safety in well controlequipment.

Aquila's DPT not only minimizes the risk of human error but also revolutionizes the documentation and organizational aspects of pressure testing. Its ability to seamlessly integrate test results into comprehensive reports and maintain meticulous records enhances compliance, facilitates better planning, and ensures a robust review process.

For operations seeking to elevate their well control equipment testing standards, Aquila Digital Pressure Testing emerges as a vital tool, streamlining processes and laying a solid foundation for safer, more efficient, and reliable operations. The transition to digital, spearheaded by solutions like Aquila, is not merely an upgrade; it's a transformative shift that propels the oil and gas industry towards a future where safety and precision are paramount.