Revolutionizing BOP Monitoring

Advancements Shaping the Industry

Blowout Preventer systems (BOP systems) are the unsung heroes of offshore drilling operations, ensuring safety and control during the extraction of valuable resources from beneath the ocean floor.

Over the years, significant strides have been made in the technology and techniques used to monitor and maintain these critical components. In this blog, we'll explore how BOP monitoring is undergoing a revolution, thanks to innovative advancements that are shaping the Oil & Gas industry.

March 9th, 2024

Join our Newsletter to stay up to date on new Advancements, Announcements & more

The Significance of BOP Systems

Before delving into the revolution, let's grasp the significance of BOP systems. BOPs, or Blowout Preventers, stand as the ultimate defense against uncontrolled hydrocarbon releases, commonly known as "blowouts." They play a crucial role as a final well control barrier during drilling operations and well interventions.

Ensuring the optimal performance of BOP systems is paramount for the safety of personnel, the protection of the environment, and the overall success of offshore projects. These systems are the backbone that not only ensures technical integrity but also safeguards safety and environmental preservation in this demanding industry.

Traditional BOP Monitoring Challenges

Traditionally, monitoring BOP systems has presented various challenges:

Limited Data Visibility

Monitoring BOPs in the depths of the ocean is no small feat. Limited data visibility and real-time updates have often hindered quick responses to potential issues.

Data Interpretation

Extracting actionable insights from the vast amount of data generated by BOPs can be daunting. It requires a deep understanding of equipment behavior and predictive analytics.

Maintenance Complexities

Routine maintenance and testing procedures can be time-consuming and costly, with downtime impacting project schedules.

The Revolution: Advancements in BOP Monitoring

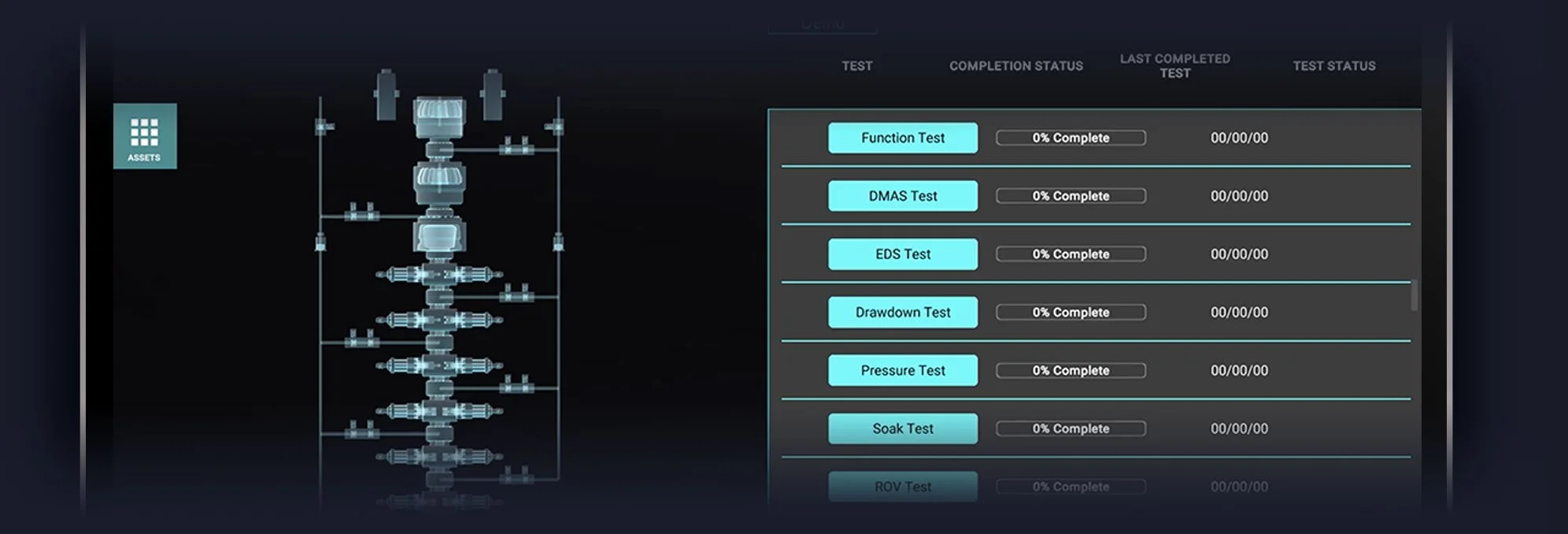

1. Digital Monitoring and Automation

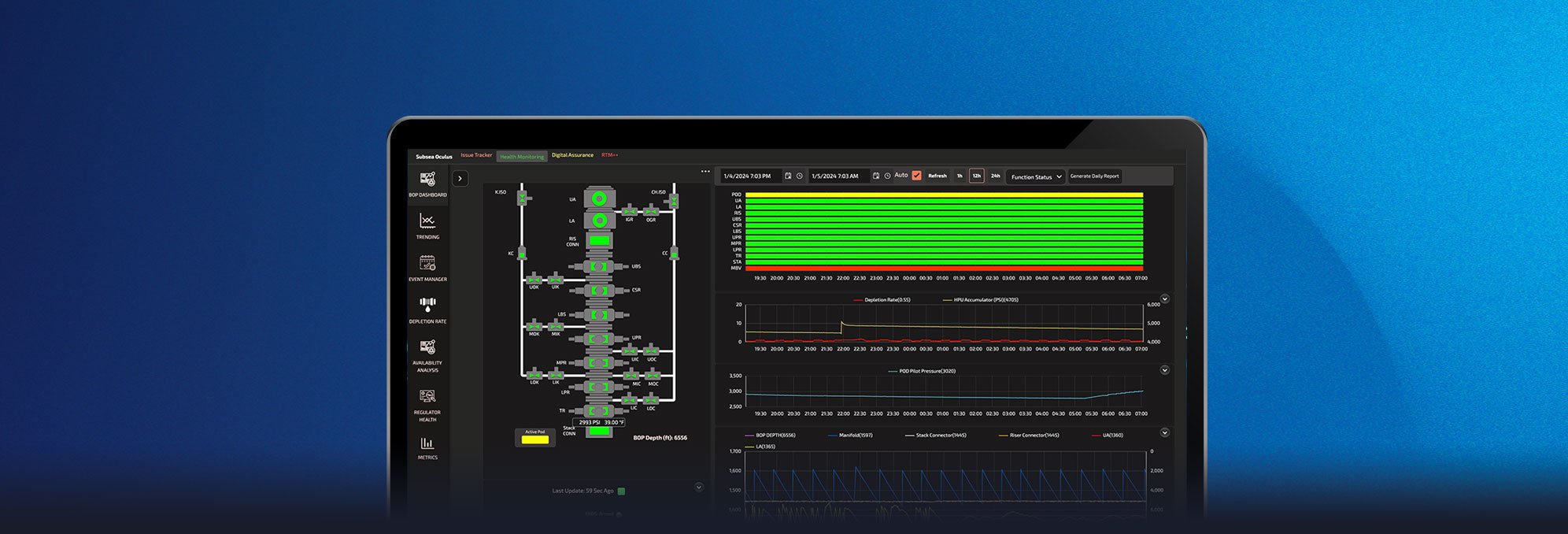

The advent of digital technology has empowered the real-time monitoring of BOP systems from onshore sites. Cutting-edge sensors, data analytics, and automation systems equip operators with instant insights into the health of BOPs, facilitating quicker decision-making and enhancing safety measures.

2. Predictive Analytics with Depletion Rate

The integration of predictive analytics algorithms has revolutionized the identification of potential issues within BOP systems, incorporating metrics such as the "depletion rate." This rate gauges the amount of fluid lost from the hydraulic system. Through a thorough analysis of this data, operators can foresee maintenance requirements, detect leaks, and proactively prevent expensive breakdowns.

Effective Communication with Rig Team in Real Time

One of the critical aspects of this revolution is the real-time communication with the rig team. Advanced BOP monitoring systems facilitate immediate communication of critical information to the rig team, enabling them to take swift action when necessary. This seamless communication enhances safety and operational efficiency.

The Benefits of the Revolution

The ongoing revolution in BOP monitoring brings several benefits to the Oil & Gas industry:

Enhanced Safety

Real-time monitoring (RTM) and predictive analytics, including depletion rate measurement, minimize the risk of blowouts, protecting personnel and the environment.Cost Savings

Condition-based maintenance reduces downtime and operational costs.Efficiency

Automation and real-time capabilities streamline operations, improving overall efficiency.

Aquila's Commitment

Aquila persists in its dedication to spearheading innovation in BOP monitoring. Fueled by a pioneering spirit and fortified by our proficiency in digital solutions, data analytics, and offshore engineering, we consistently mold the industry landscape. Our efforts aim to render offshore drilling not only safer but also more efficient and cost-effective, marking a significant contribution to the evolution of the field.

In summary, with the ongoing advancement of technology, BOP monitoring is experiencing a profound transformation. The digital monitoring revolution, integration of predictive analytics using metrics such as depletion rate, and real-time communication with the rig team collectively reshape the industry landscape. This transformative journey not only enhances the safety of offshore drilling but also significantly improves its efficiency, marking a pivotal shift in the sector.

Stay tuned for more insights and updates as we continue to explore the ever-evolving world of Oil & Gas technology. Feel free to reach out to us with any questions or to learn more about how Aquila is leading the charge in revolutionizing BOP monitoring.

AQUILA

Pioneering BOP Real-Time Monitoring Since 2019

Aquila has been at the forefront of BOP real-time monitoring (RTM) since its inception in 2019. We are pioneers in developing and implementing cutting-edge BOP monitoring systems, setting industry standards for safety, reliability, and efficiency.